Single-laser projectors continue to carry the largest share of units moving through wholesale and retail channels in the mid-range and entry-premium segments. They deliver consistent brightness at price points that align with most project budgets and cover the majority of standard AV and residential applications without frequent issues. Over the past twenty-four months, triple laser—routinely identified as tri-color laser or RGB laser—has gained noticeable traction in detailed bid packages, integrator proposals, and end-client specifications, particularly where the scope emphasizes faithful color reproduction, artifact-free motion in dynamic material, or extended periods between any field service. AV consultants, rental fleet managers, and corporate procurement specialists treat the head-to-head comparison as routine: under which conditions does the performance edge from triple laser support the incremental expenditure relative to single-laser designs? The core divergence traces directly to the light source construction. Triple laser deploys three independent laser diodes that generate pure red, green, and blue emission at the source. Single-laser engines begin with one blue laser striking a phosphor wheel to produce yellow light, then rely on sequential color filtering to approximate the remaining primaries. That conversion stage introduces variables that become apparent in deployed systems—gamut limitations, motion-induced visual disturbances, brightness decay patterns over runtime, and anticipated maintenance frequency.

What Is Tri-Color (Triple Laser / RGB Laser) Projection Technology?

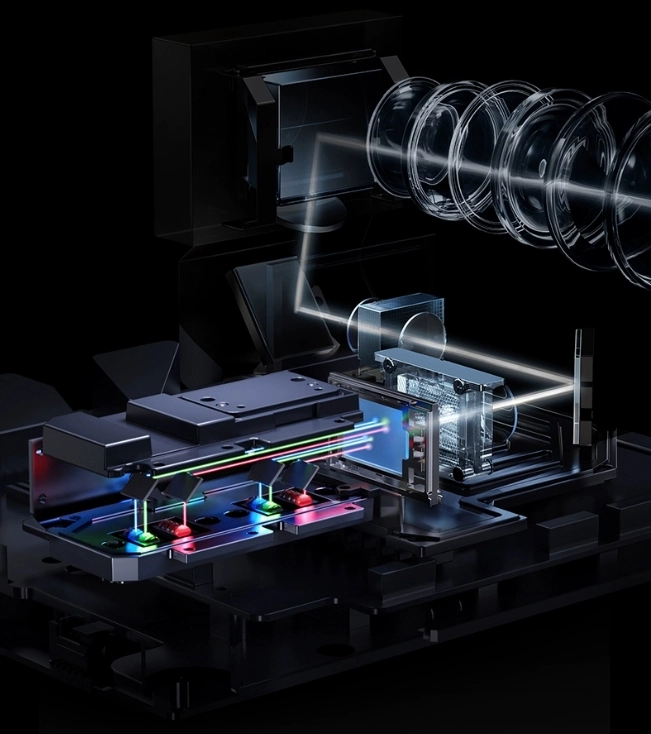

Tri-color projection constructs the image using three dedicated laser emitters aligned to the exact red, green, and blue wavelengths. The primaries combine optically in simultaneous fashion, free from sequential timing. Single-laser architectures, in contrast, direct a blue laser onto a phosphor wheel that emits a wide yellow band, which is subsequently parsed through color segments to fabricate the other two primaries.

Removing the mechanical wheel eliminates sources of optical inefficiency and timing inconsistency. The direct RGB path supports more precise modulation on each channel, producing behavior that remains more predictable when content changes from static graphics to high-speed video streams or HDR-encoded footage. Procurement groups overseeing projector deployments in corporate training facilities, multi-zone conference venues, or flexible event spaces often reference this uniformity when forecasting image matching across an installed base over multiple years.

Core Technical Advantages of Tri-Color Laser Over Single Laser

Consistent side-by-side testing, installation monitoring, and end-user reporting keep surfacing several field-relevant benefits that influence operational uptime and lifecycle economics.

Wider and More Accurate Color Gamut

Triple laser implementations commonly surpass 100% BT.2020 coverage, conforming to the color boundaries set by current UHD HDR mastering standards. Single-laser projectors encounter spectral restrictions from phosphor conversion and generally achieve only partial BT.2020 fill, with noticeable roll-off in saturated primaries such as vivid greens and rich reds. Applications dependent on exact color fidelity—brand palette compliance, merchandise imaging, or technical visualization—retain critical differentiations that hold under ambient light or extended throw distances.

Standard industry data frequently positions triple laser at 35–45% higher color volume compared with equivalent DCI-P3 references, which manifests as more authentic natural reproduction and precise branded hues in typical viewing scenarios.

Superior Color Accuracy and Elimination of Rainbow Artifacts

Independent laser primaries ensure stable chromatic coordinates without the sequential color breakup seen in wheel-dependent DLP configurations during rapid luminance shifts. Observers prone to rainbow effect—those transient red-green-blue bands on panning, scrolling, or scene changes—report substantially lower visibility when mechanical sequencing is removed.

Settings centered on presentations, including executive meeting rooms, academic lecture halls, and extended instructional programs, see reduced audience interruptions and fewer complaints related to visual discomfort.

Higher Effective Brightness and Perceived Image Pop

Channel-specific laser modulation maintains lumen delivery more evenly across content variations and operating hours. The perceptual boost tied to high saturation—commonly connected to the Helmholtz-Kohlrausch phenomenon—lends triple laser images greater apparent intensity even when ANSI lumen figures overlap with single-laser counterparts.

Single-laser phosphor-based designs exhibit progressive brightness fade as wheel material ages, while triple laser sources preserve output stability more effectively, ensuring reliable performance in rooms with uncontrolled daylight or on screens exceeding 120 inches.

Extended Lifespan and Minimal Maintenance

Triple laser light engines carry published ratings of 20,000–30,000 hours, with numerous field examples exceeding those thresholds under standard duty cycles. The absence of phosphor wheels and related drive components reduces mechanical wear points relative to single-laser architectures that retain certain replaceable elements.

Facility teams responsible for projectors in cultural venues, worship facilities, or corporate lobbies operating eight-to-twelve hours daily record fewer technician dispatches and more dependable expense projections over three-to-five-year periods.

Improved Contrast and Black-Level Performance

Accurate per-channel modulation sharpens light cutoff in shadow regions, elevating native contrast and detail preservation in dark scenes. Single-laser systems, managing a converted broad-spectrum source, allow increased stray light that compresses blacks and flattens perceived depth.

Direct comparisons of nighttime sequences or dense graphical content with dark backgrounds consistently demonstrate smoother tonal transitions and more convincing spatial rendering from triple laser configurations.

Additional Operational Benefits

Immediate image availability without preheat cycles facilitates seamless session transitions in time-constrained environments. Many configurations show improved efficiency in power consumption per lumen, relieving pressure on electrical infrastructure or thermal management systems.

Potential Drawbacks of Tri-Color Laser (and Mitigation Strategies)

Coherent laser sources can generate speckle—a low-level granular pattern—that may appear under certain screen materials or observation angles during long sessions. Contemporary optical pathways incorporate diffusers, wavelength blending, and beam shaping to suppress speckle to levels that remain imperceptible in conventional deployments.

Elevated initial costs stem from the engineering precision required for three-laser alignment. Reliable OEM partners mitigate this through configurable product tiers that align brightness targets, lens selections, and feature packages to project budget constraints.

Who Should Choose Tri-Color Laser Projectors in 2026?

Integrators serving high-end residential theaters prioritize triple laser for its HDR color accuracy and clean motion handling. Commercial AV professionals specify the technology in high-profile applications—executive briefing centers, branded retail environments, experiential museum installations—where sustained uniformity and precise color rendering reinforce intended outcomes.

Educational institutions and corporate training departments realize value from reduced maintenance across frequent daily cycles. Ultra-short throw triple laser models accommodate space-limited collaborative rooms and huddle areas, enabling substantial image sizes from minimal projection distances.

How to Choose (or Customize) a Tri-Color Laser Projector

Specification documentation should document verified BT.2020 coverage ratios, independent ANSI lumen measurements, and speckle mitigation performance. DLP platforms integrated with triple laser generally provide the pixel-level sharpness and response characteristics required for mixed static/dynamic content.

Wholesale and OEM procurement should evaluate suppliers on optical tuning capability, firmware customization scope, and manufacturing consistency. Tailored engine designs allow precise adjustment of projection parameters, signal processing, and connectivity to match specific deployment objectives.

Shenzhen Toumei Technology Co., Ltd. Overview

Shenzhen Toumei Technology Co., Ltd. has concentrated on DLP projection systems since 2013, managing the full process from research through manufacturing and distribution in Shenzhen. The range includes smart portable projectors, ultra-short throw engines, and feature-dense models with laser autofocus, elevated brightness, and broad integration options. Certified as a national high-tech enterprise, Toumei upholds strict quality disciplines and offers extensive OEM/ODM partnership support, providing a consistent supply base for distributors and AV system integrators.

Conclusion

Triple laser projection establishes clear engineering advantages over single-laser approaches in color gamut span, artifact suppression, brightness holding power, and operational longevity. These improvements resolve ongoing issues in professional AV work—image uniformity across conditions, minimized service interruptions, and accurate color delivery—that ultimately shape project outcomes. With content pipelines and distribution channels steadily advancing toward broader gamuts and greater dynamic range, tri-color technology stands as a technically sound specification for forward-looking installations.

Triple laser projectors maintain broader BT.2020 coverage and color stability through heavy usage cycles, preserving accurate corporate graphics, brand identities, and visual detail in conference facilities, retail settings, and digital signage networks where single-laser designs show gradual loss of saturation.

Tri-color systems generate red, green, and blue light simultaneously using dedicated lasers, bypassing the sequential color wheel responsible for rainbow artifacts in conventional DLP projectors and producing cleaner motion transitions.

BT.2020 defines the wide color space for modern HDR material; triple laser projectors commonly achieve over 100% coverage, rendering richer, truer hues and saturation levels that single-laser phosphor-limited designs fall short of matching.

Speckle can introduce subtle grain from coherent light coherence, but present-day triple laser designs apply diffusion techniques, wavelength diversity, and beam shaping to keep it negligible under standard viewing conditions.

Triple laser sources deliver 20,000–30,000 hours of reliable output, frequently outperforming single-laser systems in the field by sidestepping phosphor wheel degradation that slowly affects brightness and color equilibrium.